NEW “FOAM FLAPS” HELP HVAC MANUFACTURERS SPEED PROCESS AND ELIMINATE STRAY FOAM CLEAN-UP

A major manufacturer of HVAC equipment had to break into a robotic cell to install metal plugs into the holes into which their door foam was injected. This stopped the robot, for safety reasons, creating a production delay, and allowed foam to escape before the plug was installed. This also resulted in additional clean-up work before the panels could be installed.

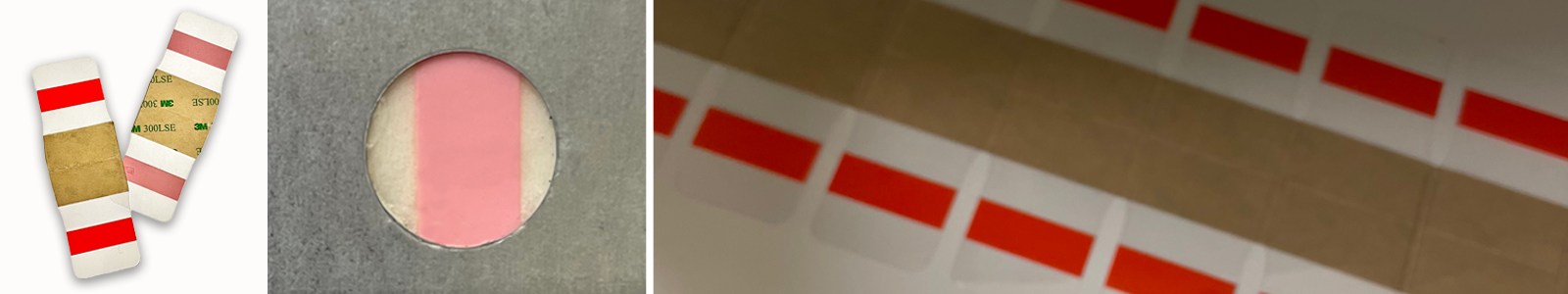

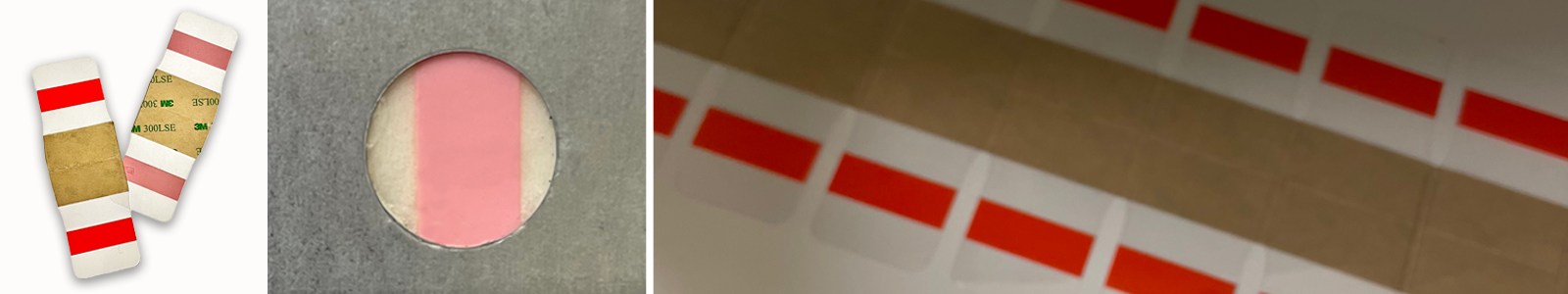

Allegis proposed adhering a clear film flap inside the panels by an adhesive strip that would act like a one-way “doggy door,” allowing the nozzle into the panel to inject the foam, but not allowing the foam out as it expanded and cured. The customer suggested putting a red stripe onto the otherwise clear flap so that they could quickly ascertain if the panel was filled or not.

Besides the time saved in the filling operation, a lot less foam escaped, thus eliminating the time spent cleaning it off the panels.

Foam flaps can be custom-sized based on the door geometry and are produced at Allegis’ Rhopac division in Libertyville, IL.

Contact your Allegis representative for more information, a sample, or a consultation with one of their experienced business development managers.